- #Pouring temperature in magmasoft serial#

- #Pouring temperature in magmasoft software#

- #Pouring temperature in magmasoft windows#

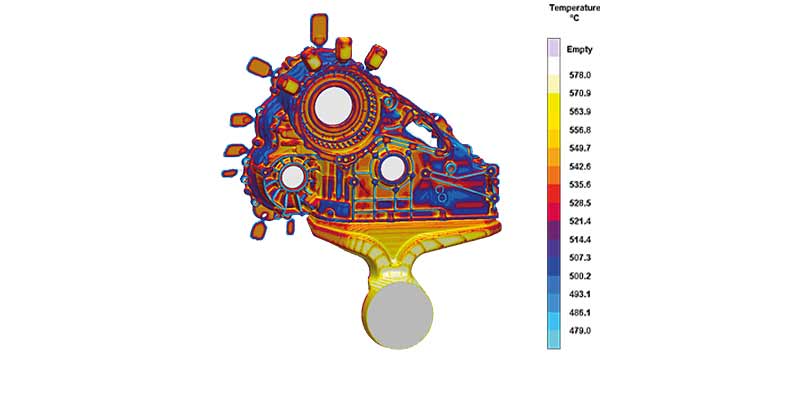

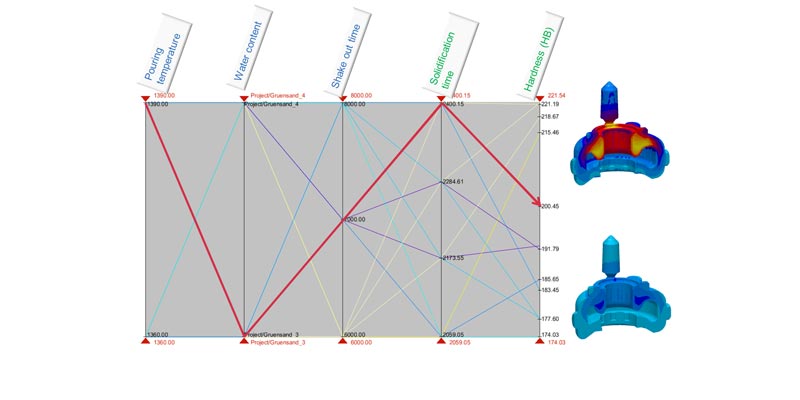

One novel solution is to leverage the design freedom of CAD-based solid modeling to introduce unique mold features specifically for housing sensors ( Internet of Things) within the mold to enable the collection of a diversity of data at manifold locations: temperature, pressure, moisture, gas chemistries, motion of the molds and internal cores (shifting or rotation), and magnetic field. Simulations of castings are more important than ever, and empirical in situ sensor data are required to validate high fidelity computer modeling (e.g., MAGMASOFT ®). However, an increase in design complexity invites more challenges in terms of understanding and managing both the thermodynamics and physics of the casting process. With printed sand molds, castings can be optimized with regard to the strength-versus-weight trade-off and structures such as periodic lattices are now available within molds that are not possible with traditional casting technology. Modules for simulating stresses of the component after casting, heat treatment, or machining and the exchange of information based on simulation results, assures the design of cast parts for their performance.Additive manufacturing, also commonly referred to as 3D printing, stands to transform sand casting with binder jetting technology that can create sand molds with unmatched geometric complexity. MAGMA HT thermal, MAGMAstress, MAGMAlink, MAGMAdielife Products and functionalities for the prediction of core shooting, gassing, and purging and the assessment of die life aid in making the best use of available knowledge. Process modules allow the consideration of specific process requirements and to control the manufacturing process. MAGMAhpdc, MAGMAlpdc, MAGMApermanent mold, MAGMAwheel, MAGMAinvestment casting Material-specific modules allow the prediction of microstructures and properties and consider alloys and metallurgy. MAGMASOFT® can easily be linked to additional modules for specific processes, materials or quality aspects. Database module to manage thermo-physical and other relevant process data required for simulation.Easy quantitative assessment of virtual Design of Experiments or optimization runs.Result perspective for comprehensive visualization and evaluation of simulation results.Interactive and automatic result evaluation: Several perspectives can be opened and edited at the same time.

#Pouring temperature in magmasoft serial#

Simulation programs for the calculation of mold filling, solidification, cooling and serial casting applications.Definition of virtual designs and parameters for optimization runs.

#Pouring temperature in magmasoft windows#

#Pouring temperature in magmasoft software#

The software can be applied for optimized process robustness and part quality from conceptual to final component design, during the tooling layout and prototyping, all the way through to the production and heat treatment processes. A modular software design covers the complete process chain of cast components.

0 kommentar(er)

0 kommentar(er)